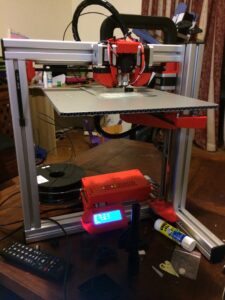

It finally arrived. I’m now the proud owner of a Felix 3.0 dual extruder 3D Printer. After a few SW Makers Meetings where I had to watch the printing happening I thought I’d buy myself a 40th birthday present.

I splashed out and added most of the extras, dual extruders, LCD panel and I made sure it was in Ferrari Red so it goes faster.

After almost 5 nights of building and testing, I finally got it together and worked out all the kinks in the system. (Yes, that’s code for “I put it together and wired it wrong a couple of times”, it is a learning process after all.

The first ever print from the machine (besides those I consider testing, that didn’t even stick to the print bed) was a calibration block. It prints a super thin walled rectangle to test the reliability and adjustment of the printer. I think it worked out well.

I then moved onto the tool holder. It’s a small block which clips onto the frame of the printer and holds a set of tweezers used to clean away excess filament while printing. It took 3 prints but I finally managed to get a good print from it.

Apparently I’ve got a lot to learn about 3D printing but hopefully it won’t be too long before I’ll move onto making some really cool parts for other projects around the cave.